Descripción

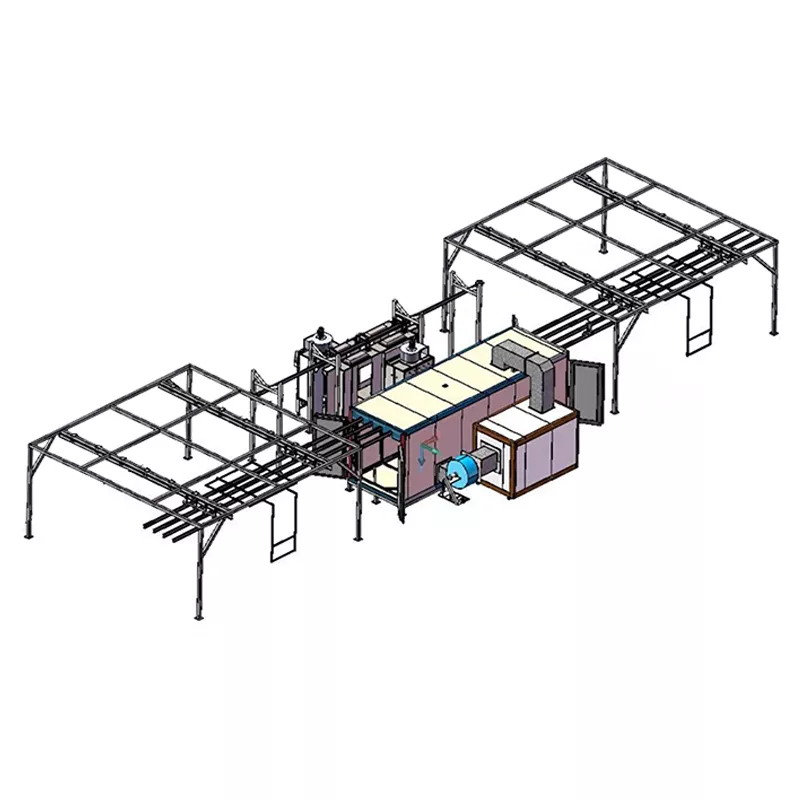

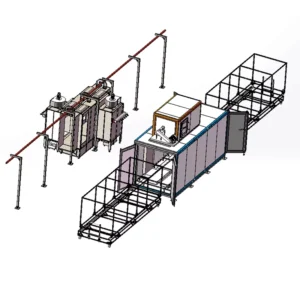

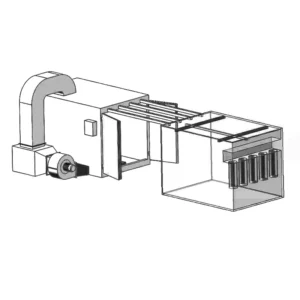

Manual Powder Coating Conveyor Line

This powder coating line is ideal for continuous batch production, based on manual operation with overhead conveyor, includes pass thru powder coating booth and curing ovens, as well as manual powder painting machines.

COLO-191S Powder Coating Spray Gun

COLO-191S manual powder coating gun is developed for easy and efficient job, suits for both beginners and specialists. Based on COLO advanced technology, especially complex parts can be perfectly coated with this model.

Configurations and Features

1. Digital controller allows precise setting and reading electric data

2. Three pre-set application programs stand for flat parts, profiles and re-coating

3. 100kv manual spray guns delivers high transfer efficiency with long time working

4. 60lbs fluidizing powder hopper is welled sealed to avoids damp and contaminated.

5. Flexible trolley with wheels can be moved everywhere

6. The anti-static powder hose is smooth for powder conveying.

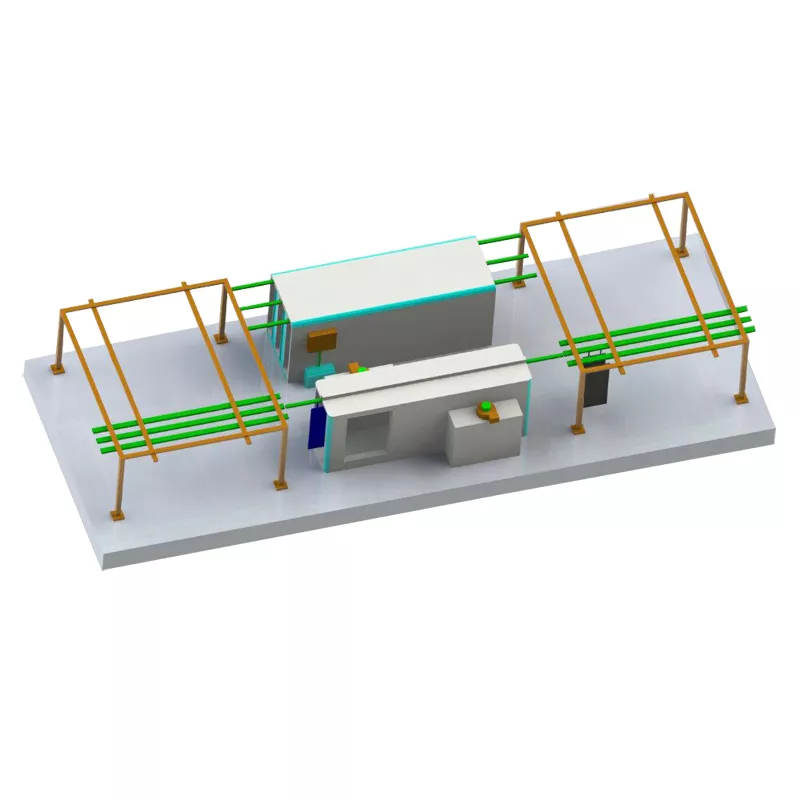

COLO Tunnel Powder Spray Booth

This tunnel powder coating booth has 2 working station allows parts recieving coating from both side, parts enter the booth from one entrance and exit from the other through conveyors, continuous coating increases efficiency and ensures application quality.

Features

Operator dimensions: Width1.1m x Height1.8m x Depth4m

Power supply: Electric

Volatge: as required

Frequency: 50-60Hz

Filters: Polyester

Filters hang type: easy for change

Filter cleaning system: Pneumatic

Fan: 2 sets, 4kw

Track Powder Coating Oven

This powder coating oven installed with conveyor is designed to carry heavy materials into the oven for continuous production, can be heated by electric, gas or diesel as required.

A circulation fan cycles hot air uniformly and keeps even temperature in the chamber. Our powder coating ovens features environmental friendly, reducing operating cost and curing more parts everyday.

Specifications

Working dimension: Width 1.8m x Height 2.1m x Depth7m

Power supply: Gas/ LPG/Diesel

Voltage/Frequency: As required

Burner: Italy Riello, 30,0000kcal

Warm-up time:15-30 min. (180°?C)

Temperature stability: < ± 3-5°C

Max. Temperature: 250°C

Ventilation performance1131-2565m3/h

Fan Motor power: 7.5kw

Valoraciones

No hay valoraciones aún.