¡Tu carrito está actualmente vacío!

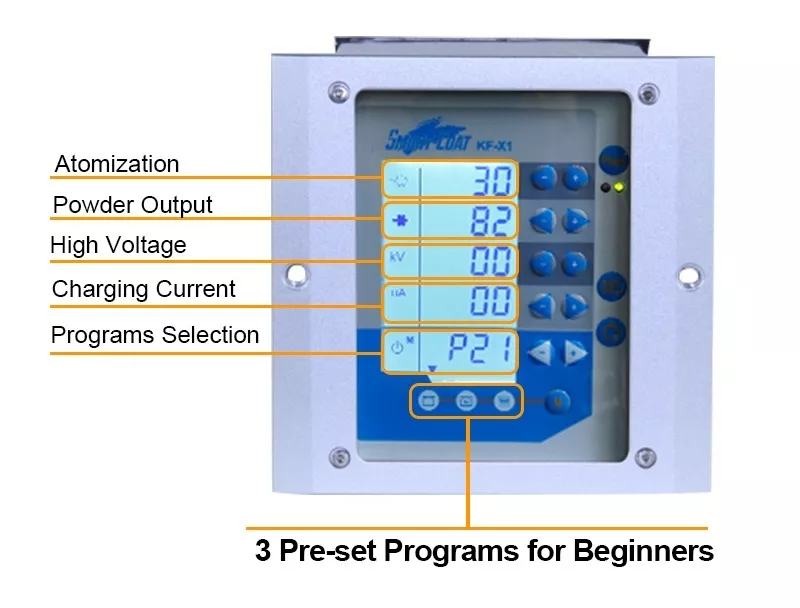

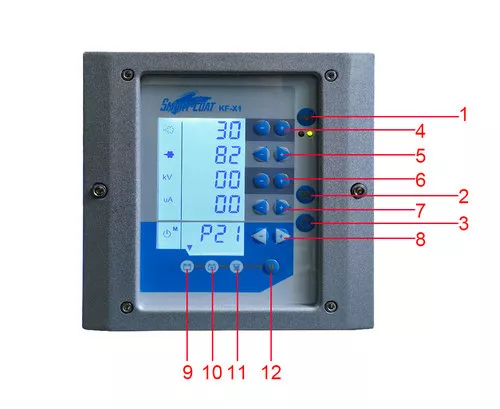

KF-X1 Controller Introduction

Control crucial coating parameters and obtain excellent results and measurable system optimizations with KF-X1 controller.

Descripción

Basic Benefits

- Flexibly, precisely control all the electrostatic and pneumatic parameters to optimize processing.

- Reproducible regulations to improve the film thickness consistency.

- Always applies right amount powder to objects for a significant powder saving.

- Create excellent uniform finish even with challenging powders or complex workparts.

- Pre-set and customized application programs are easy for beiginners, powerful for advanced users.

- Clear interface allows ergonormic and intutive handling of the control.

DVC Technology

Digital Valve Control (DVC) technology means the conveying and supplementary air to the venturi injector is regulated by digital valve, thus it gives precise regulations of pneumatic parameters, such as powder output atomizing air.

- It is easy for every powder coater to find the right powder amount to objects consequently in very significant powder savings.

- Precise powder output application leads to repeatable application performances and improve the film thickness consistency.

- Always remain stable powder output over time for the best application results.

- Precisely regulate the powder output for all the guns at the same value, results in a more uniform powder distribution on the surface.

Individual Control of Current and Voltage

Voltage and current are the bottom line in the electrostatic powder coating process. Most common models only allow to adjust voltage while COLO-191S & KF-X1 can flexibly and precisely adjust both current and voltage. which helps to optmize the amount of charges for powders/objects.

Using a control unit that has the ability to monitor both of these settings is a definite advantage to ensure maximum efficiency and uniformity of coating. such as improving penetrating into corners, overcoming Faraday Cage Area, Orange Peel Effect, etc.

3 Pre-set Application Programs

The 3 pre -set application programs, based on COLO 10 years experience, are a great help for powder coating beginners, easily handling different shapes of workparts.

Flat coating program: ideal for the application of panels or flat shape workparts.

Corner coating program: perfectly designed for the application of three dimensional parts with complex shapes such as profiles.

Recoating program: optimized for the application of parts which have already been coated .

20 Customized Programs Library

This feature is great for quality control when more than one operator may use the gun during the day as in the case of a second shift. By storing the settings as recipes, you can safeguard the same quality results time after time no matter who’s holding the gun.

Debes acceder para publicar una valoración.

Valoraciones

No hay valoraciones aún.