¡Tu carrito está actualmente vacío!

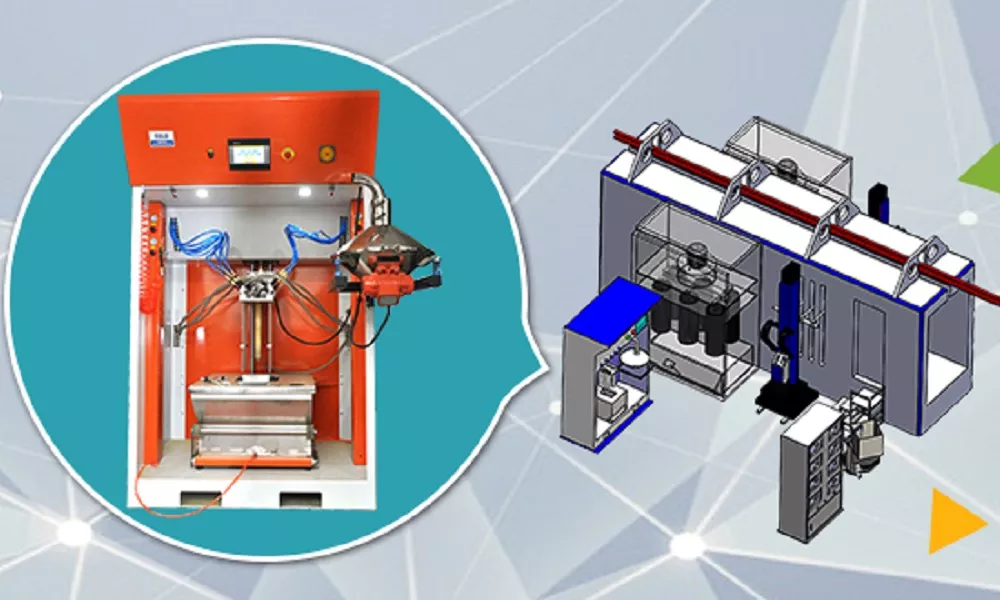

Automatic Powder Supply Center COLO-6000

Automatic spraying line powder supply center tends to improve production efficiency and application quality. With excellent features of: 1.PLC control system with touch screen interface 2.Powder position tracking and lack alarming 3.Fluidizng barrel feeding or original box feeding 4.Automatic mixture of recovered and fresh powders 5.Automatic powder cleaning through devices and pipelines. Model:COLO-6000 Brand:COLO

Descripción

Automatic Powder Supply Center COLO-6000

The powder feed central system is designed for continuously, uniformly, quantificationally feeding powders to spraying equipment in automatic powder coating line.

Since the cleaning of componenets and pipelines is automatically carried out by program, it is ideal for fast color change demands. Powder supply center maintains comfortable indoor environment by transferring partciculates during cleaning.

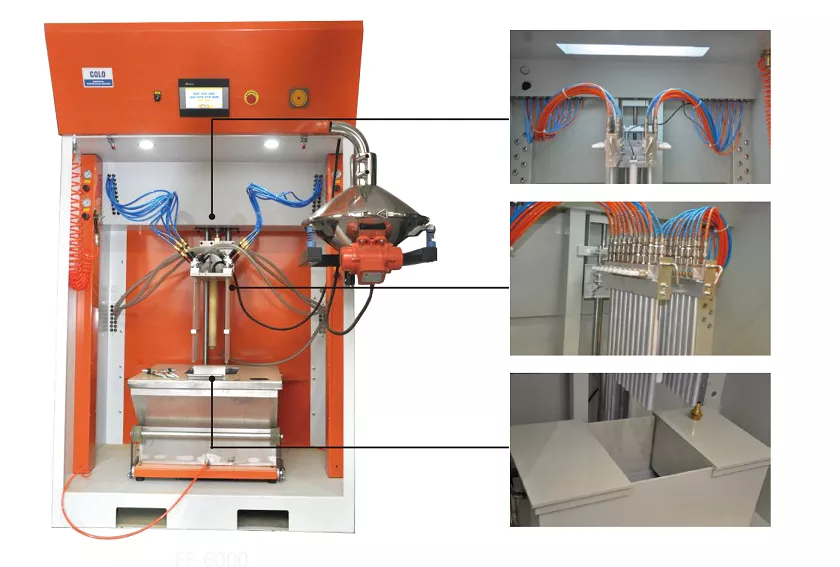

Powder Supply Center Configurations & Features

- A sensor detects the powder position in the barrel, warning the lack of powder for continuous feeding.

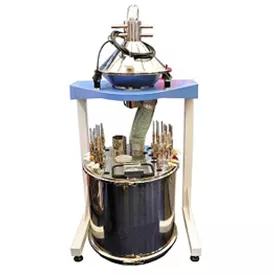

- 100lbs capacity powder barrel has a microporous plate which is meticulous and uniform for perfect fluidizing.

- A vibration powder siever ensures the purity of recovery powders, and increases powder utilization.

- Pulse-jet device automaticlly cleaning spray guns, injectors and pipeline rapidly

- PLC control system with touch screen panel and keyboard input, user-friendly to debug and operate.

Powder Supply Center Parameters

1. Power Supply: 1P 220V AC (110V available)

2. Power: 500W

3. Air pressure: 0.6-0.8MP

4 Can be equipped with up to 16 powder pumps

Debes acceder para publicar una valoración.

Valoraciones

No hay valoraciones aún.