Descripción

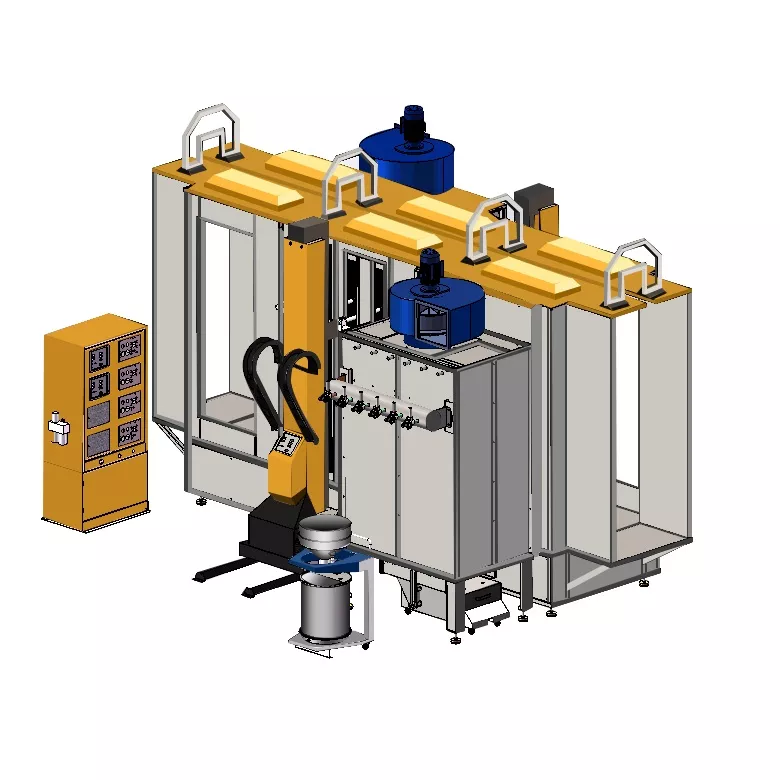

Reciprocating Automatic Powder Coating Booth System

It is a highly-efficient solution in automatic powder coating line. Reciprocating powder guns ensures productivity and uniformity, Automatic spray booth creates clean working condition with high powder recycling rate. Powder management center ensures stable powder output.

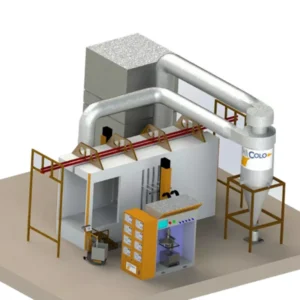

Automatic Powder Booth Features

1. Designed with double automatic station for reciprocator powder coating and double manual station for repair coating.

2. Two groups of cartridge filter ensures effective recovery of oversprayed powders.

3. Pulse-jet automatic filter cleaning technology takes full utilization of powders and extent filter life for many years.

4. All functions, parameters can be flexiblely controlled on the PLC panel, such as fan start, filter cleaning, booth cleaning.

Automatic Powder Coating Gun System

1. A central control cabinet combines all powder gun controller for integrated operation, space-saving and easy maintenance.

2. The 100kv spray gun powerfully charge powders increasy coating efficiency.

3. The Intelligent controller has one-touch preset buttons suitable for beginners handling different metal shapes.

4. Based on COLO 10 years technology, reliable system with minimum maintenance.

Powder Coating Reicprocator

1. Driven by belt and controlled via PLC, ensures stable and precise movement. and increases uniformity and quality consistancy, reduces powder consumption.

2. With high stability to carry up to 24 of spray guns for smooth and gentle motion

3. Moving stroke and speed can be adjustable on the digital screen, which allows to store 20 working programs

4. Robust, reliable, and easy to maintain reicporcator with space saving design.

Powder Management Center

1. Continuously feeding fresh powders and uniformly mixing with recycled powders, increases powder utilization and ensures application quality. And with excellent features of:

1. Highest cleaning efficiency due to automatic cleaning of all powder-carrying components

2. Integrated control of all components of the powder coating line

3. Powder level detection ensure constantly available powder quantity.

4. Ultrasonic sieving of fresh and recovery powder for maximum sieving performance.

Valoraciones

No hay valoraciones aún.